Respiratory Protection

Respiratory Protective Equipment is essential for activities where there is a risk of inhaling harmful substances or encountering oxygen-deficient environments.

Selecting the correct equipment and ensuring its proper maintenance must be based on the specific type of work, the associated risks, and compliance with applicable regulations and standards. These regulations may vary depending on the work environment and governing frameworks.

Improper selection, use, or maintenance of Respiratory Protective Equipment can expose users to hazardous substances, leading to serious health issues or, in worst cases, fatal outcomes.

There is a wide range of solutions available tailored for various environments and applications, including firefighting, military, and industrial settings.

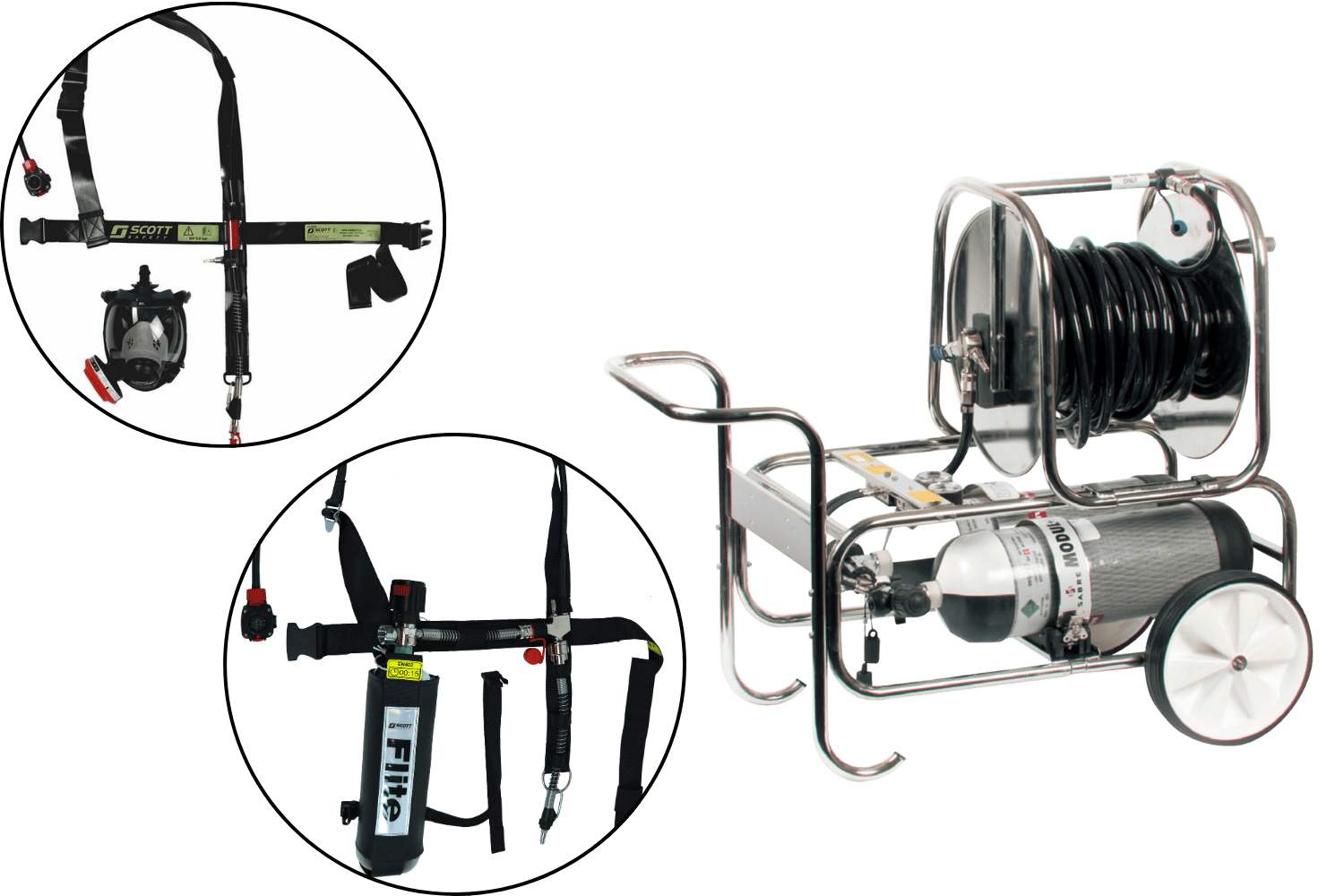

SELF CONTAINED BREATHING APPARATUS:

The Self-Contained Breathing Apparatus (SCBA) provides users with full mobility while offering a high level of protection by supplying compressed air from a high-pressure cylinder. This air is regulated through a pneumatic system to ensure safe and controlled breathing conditions.

SCBAs are used as Personal Protective Equipment in environments with non-breathable atmospheres, as emergency escape devices from confined spaces, and by emergency and rescue teams, including firefighting operations.

The duration of use depends on the volume of compressed air stored in the cylinder, the wearer’s physical activity, and their physical condition. Advances in composite materials have enabled the production of air cylinders that store greater volumes of compressed air while significantly reducing weight, both critical advantages for users.

AIRLINE BREATHING APPARATUS:

The Airline Breathing Apparatus offers an effective respiratory protection solution in environments where clean breathing air cannot be guaranteed, and where using an SCBA is not feasible due to space constraints or extended operational duration.

By supplying air through a medium-pressure hose, it significantly reduces the weight the user must carry compared to an SCBA, while still providing a high level of respiratory protection for long-duration use.

Its modular design allows users to customize the system to fit specific operational requirements across various hazardous areas, especially where a permanent air supply infrastructure is available. The system enhances freedom of movement by allowing the use of a filter for environments without oxygen deficiency but with airborne contaminants, while also enabling a switch to the airline supply with positive pressure protection when needed.

Additionally, an emergency air supply cylinder can be integrated. If there is a failure in the airline supply, the apparatus automatically switches via a changeover valve to the emergency cylinder, providing approximately 10 to 15 minutes of air, enough time for the user to initiate emergency protocols.

ESCAPE SETS:

Escape Sets are designed for quick and easy activation by the user. This respiratory protective equipment provides sufficient air supply to enable the wearer to safely exit from a hazardous atmosphere within a specified time range.

Open Circuit Emergency Escape Breathing Device (EEBD):

The open circuit EEBD supplies breathing air to the user via a compressed air cylinder. Once activated, air flows through a pressure reducer at a constant rate of approximately 35–40 litres per minute. This constant flow creates a positive pressure inside the hood, allowing exhaled gases and unbreathable air to be expelled through an exhalation valve. Typically, these devices provide between 10 and 15 minutes of respiratory support.

Advantages of open circuit EEBDs include a lower initial purchase cost and the ability to be rebuilt after use. However, they require regular servicing by approved companies. Additionally, the air cylinder must undergo periodic internal inspections and pressure testing, which increases maintenance costs.

Closed Circuit Emergency Escape Breathing Device (EEBD):

Closed circuit EEBDs supply oxygen instead of compressed air. Exhaled CO2 is chemically scrubbed from the circuit while oxygen is replenished and moisture levels are managed to maintain a safe breathing environment. The SEMMCO Marine EEBD is approved to provide 15 minutes of operational time under marine standards and 20 minutes under industrial approval. If the user remains at rest, with lower oxygen consumption, operational time can extend up to 60 minutes.

The SEMMCO EEBD is compact, lightweight, and cost-effective when not in use. It requires only simple periodic visual inspections and does not need certified servicing. The device must be replaced every 15 years.

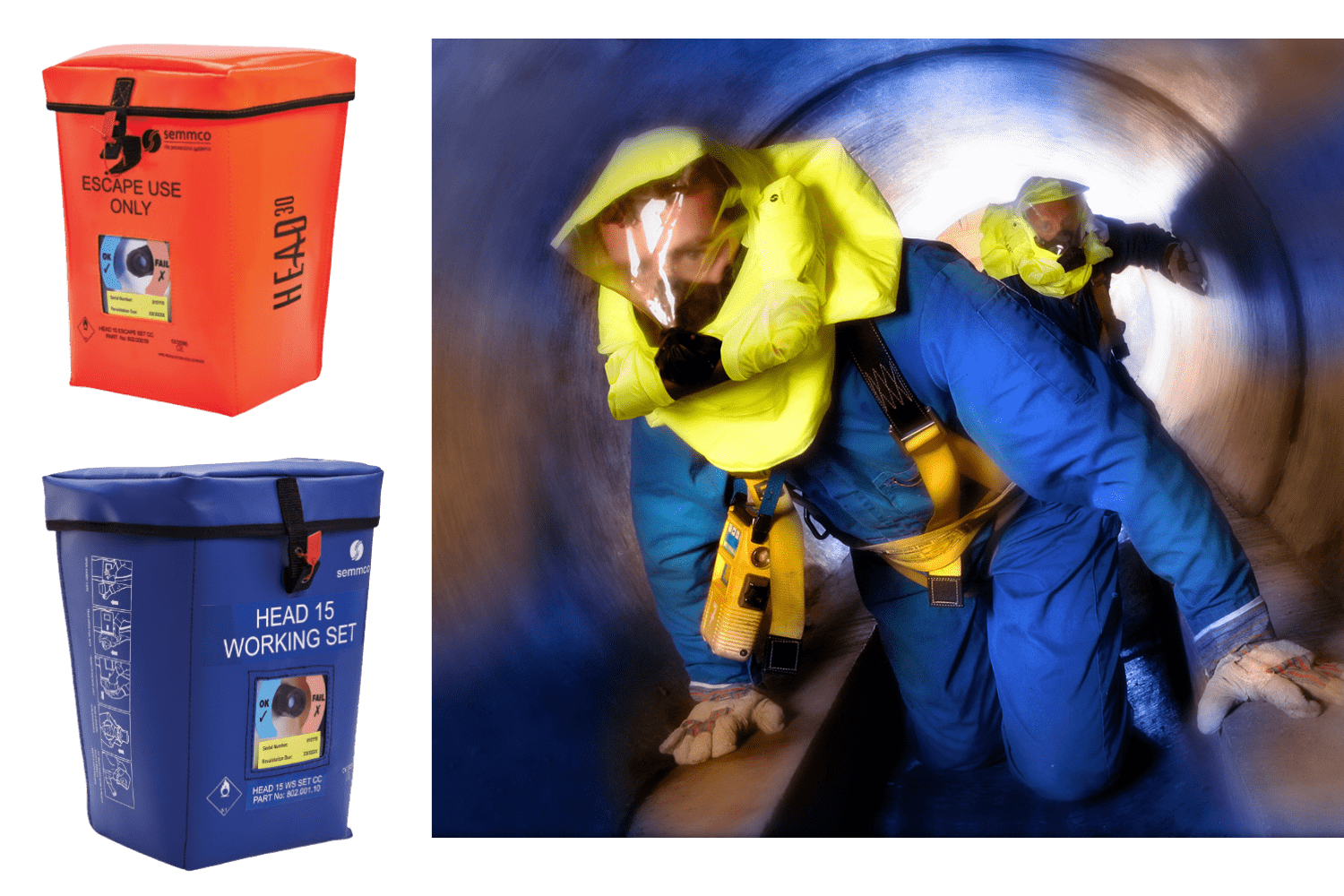

SEMMCO HEAD Escape and HEAD Working Rescue Sets:

The SEMMCO HEAD sets are self-contained, short-duration oxygen rebreathers available in various models and durations. Their design is based on potassium superoxide (KO₂), which safely provides a continuous supply of oxygen, allowing the user to breathe in hazardous environments without the bulk and weight of high-pressure air cylinders.

When the user exhales into the inner mask, the breath is directed to cartridges located on both sides of the hood. These cartridges contain KO₂, which scrubs the exhaled CO₂ and simultaneously releases fresh oxygen to be inhaled by the user during the breathing cycle.

The HEAD sets are automatically activated upon removal from their packaging and feature visual and audible alarms at three stages: initiation, two-thirds consumption, and end of effective duration. Both the HEAD Escape and Working Rescue sets have a 12-year shelf life and require only visual inspections at the 6th and 9th years.

- SEMMCO HEAD Escape: Available in 10, 15, or 30-minute durations.

- SEMMCO HEAD Working Rescue: Available in a 15-minute duration.

BREATHING AIR COMPRESSORS:

We offer a wide range of breathing air compressor solutions tailored for diverse environments and applications, including firefighting, military, industrial, and diving operations.

Our turnkey services cover everything from equipment selection and system design to installation, setup, and commissioning. We provide certified after-sales technical support through Sauer and Bauer Compressors for regular inspections, routine maintenance, repairs, and system upgrades.

- Stationary compressors

- Portable compressors

- Breathing air storage systems

- Air purification systems

- Filling stations

- Accessories and spares

Air quality tests service:

- EN 12021:2014

- NFPA 1989