Fire Extinguishers

Fire extinguishers are typically used as the first response to control a fire in its early stages, preventing it from developing into a more serious or uncontrollable situation. Their proper selection should be based on the classification of fire risks or types, the extinguishing agent, fire rating, quantity of fire extinguishing agent, environmental, and applicable regulations.

CLASIFICATION OF FIRES

Several standards define the classification of fires. EN 2 and ISO 3941:2007 follow the same approach and are primarily used in Europe, Africa, Asia, and Oceania, while NFPA 10 is the most common standard in North and South America.

These classifications are based on the materials or substances involved in the combustion process. Selecting fire extinguishers according to these standards is essential to ensure the use of the appropriate equipment for each type of fire. In addition, other specific risks should also be taken into consideration.

Class A Fires according to EN 2, ISO 3941 & NFPA 10:

Fires involving solid materials, usually of organic origin, where combustion occurs with the formation of glowing embers. Examples: Wood, paper, cardboard, plastics, rubber, coal, etc. These fires are common in homes and offices due to the presence of furniture, curtains, and other combustible materials. They generally require a high ignition temperature for the solid to generate sufficient flammable vapours to sustain combustion.

Class B Fires according to EN 2, ISO 3941 & NFPA 10:

Fires involving flammable liquids, of a liquid nature, or liquefiable solids. Examples: Gasoline, alcohol, paint, asphalt, paraffin, grease, etc. These are typically found in industrial environments, though they can also occur in residential or commercial settings. In their liquid phase, these substances emit flammable vapours that can easily ignite. Class B fires are characterized by a low flash point, meaning they can ignite readily when exposed to an ignition source.

Class C Fires according to EN 2 & ISO 3941:

Fires involving gaseous substances that are in a gaseous state at room temperature. Examples: Butane, methane, hydrogen, acetylene, etc. These gases are often used under controlled conditions in industrial processes, as well as in boilers and kitchens. Class C fires generally have a very low flash point, so even a minor electrostatic discharge can initiate combustion.

Class D Fires according to EN 2, ISO 3941 & NFPA 10:

Fires involving reactive metals or metal dusts. Examples: Magnesium, sodium, potassium, titanium, aluminium fines, etc. These combustibles are often found in laboratories and industrial facilities. Some Class D metals react violently or explode on contact with water, so specialized extinguishing agents and safety procedures are required.

Class F according to EN 2, ISO 3941), and Class K according to NFPA 10:

Fires involving cooking oils, fats, or greases of animal or vegetable origin. Examples: Olive, sunflower, peanut, and canola oils; pork fat, etc. Although NFPA EN2 and ISO 3941 use different designations (K vs. F), both standards describe fires associated with cooking equipment, particularly in commercial kitchens and restaurants, and adopt similar safety approaches.

Fires Involving Energized Electrical Equipment under EN 2 & ISO 3941:

Unlike NFPA 10, EN 2 and ISO 3941 do not classify these fires separately, since electricity itself is not a fuel. However, specific precautions must be taken when energized equipment is involved to ensure safe selection of extinguishing agents and procedures.

Fires Involving Lithium Batteries

Fires caused by thermal runaway in lithium batteries are not classified under any current standard. Nevertheless, such incidents can be extremely difficult to control, and specialized fire suppression products are now available on the market, certified and marked specifically for use on lithium battery fires.

FIRE EXTINGUISHING AGENTS

A fire extinguishing agent is the active substance contained within the extinguisher vessel that, through its physical or chemical properties, is used to suppress and extinguish fires. There are several types of extinguishing agents some of them multipurpose, so it is crucial to understand the fire classifications defined by the relevant standards and to select the appropriate extinguisher for the specific fire risks present in the protected area. This ensures effective fire suppression and prevents the use of unsuitable extinguishers, which may be ineffective or even hazardous due to their design or agent type.

Below are some of the most commonly used fire extinguishing agents for reference; however, because of the wide range of products, approvals, and standards available on the market, it is essential to check the extinguisher label to identify the classes of fire it can safely be used on, and to follow the manufacturer’s instructions for proper use and maintenance:

Water Additive Fire Extinguishers

Also known as Foam Fire Extinguishers, depending on the type of additive used, this extinguishing agent is recognized under EN2 and ISO 3941 standards. It can be effective against Class A, Class B, and low-voltage electrical fires (when discharged from a safe distance). In some cases, it is also suitable for Class F fires and even lithium battery fires, depending on the specific formulation and certification.

Water additive extinguishers are increasingly used as an alternative to dry powder extinguishers in shopping areas and other similar environments where Class A and B risks are present. They offer advantages such as better visibility during discharge and easier cleanup after use, which is beneficial in occupied or commercial spaces.

Wet Chemical Fire Extinguishers

Wet Chemical Fire Extinguishers are widely used under the NFPA 10 standard. The extinguishing solution typically has a pH of 9.0 or lower and is effective against Class A and F fires under EN2 and ISO 3941, as well as Class A and K fires according to NFPA 10. This extinguishing agent is particularly suitable for commercial kitchens and restaurants, where cooking oils, fats, and greases are common fire hazards. The wet chemical reacts with the hot oil to form a soapy layer (saponification), which cools the surface, suppresses vapours, and prevents re-ignition.

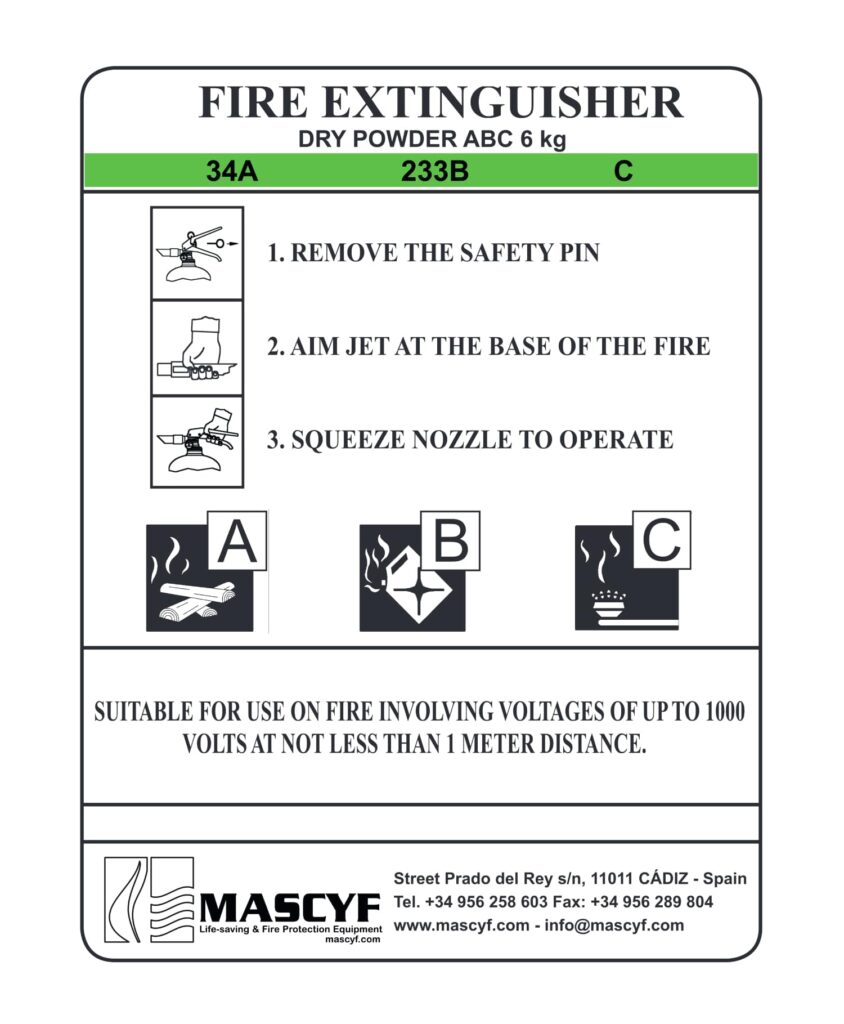

Dry Powder Fire Extinguishers

The most common and widely used type of Dry Powder Fire Extinguisher is the Multipurpose ABC, known for its versatility in combating multiple classes of fire—Class A, B, and C under EN2, ISO 3941, and NFPA 10 standards.

This extinguishing agent is cost-effective, non-toxic, non-abrasive, and non-corrosive; however, due to its fine particle size (typically under 500 microns), it can impair visibility and potentially cause respiratory irritation when discharged in enclosed spaces.

Although not chemically corrosive, the powder’s light, moisture-absorbing particles can lead to medium- or long-term damage to electronic equipment if not properly cleaned after discharge. Therefore, it is not recommended for use in areas containing sensitive electronics or precision instruments.

Common Types of Dry Powder Agents according to EN2, ISO 3941 & NFPA 10:

- ABC Powder: Typically composed of monoammonium phosphate with additives. Effective on Class A, B, and C fires.

- BC Powder: Usually based on sodium bicarbonate with additives. Effective on Class B and C fires.

- D Powder: Formulated with sodium chloride and other additives. Specifically designed for Class D fires (combustible metals).

Carbon Dioxide (CO2) Fire Extinguishers

Carbon dioxide stored in a Fire Extinguisher is mostly in a liquefied state under high pressure, within a temperature range of -20°C to +60°C.During discharge, CO2 rapidly changes from liquid to solid particles of dry ice, then quickly evaporates into gas. In its gaseous form, CO2 displaces the oxygen around the fire, suffocating it, while simultaneously cooling the contact surface.

It is suitable for Class B fires under EN2 and ISO 3941 standards, and for Class B and C fires under NFPA 10.

CO2 fire extinguishers are highly effective for electrical fires, as the agent is clean (leaves no residue), non-contaminating, odourless, and non-conductive. However, due to the thermal shock it produces, it may damage sensitive electronic devices.

This type of extinguisher is not recommended for use in areas with strong air currents and should be applied with caution in confined spaces because of its oxygen-displacing effect, which can pose a respiratory hazard.

Clean Agent Fire Extinguishers

Clean Agents are highly valued for their high fire suppression effectiveness, low-pressure storage, electrical non-conductivity, non-corrosiveness, and the fact that they leave no residue. Additionally, they pose a very low risk to occupants, making them ideal for use in occupied spaces. Fire suppression is achieved through heat absorption and interrupting the chemical reaction of the fire.

Several Clean Agents are available on the market, with Halotron and FK-5-1-12 being the most common in fire extinguishers. These agents are suitable for electrical fires, Class A and B fires under EN2 and ISO 3941 standards, and Class A, B, and C fires under NFPA 10. While Clean Agents have the highest upfront cost, they are the most cost-effective solution when protecting expensive electronic equipment. Similar to CO2, they are not recommended for use in areas with strong air currents, due to their rapid evaporation and dispersal.

RATING OF FIRE EXTINGUISHERS

The rating of a fire extinguisher is assigned by an independent testing organization after conducting multiple real fire tests based on the applicable standards. The fire extinguisher’s performance during these tests determines the scope of its certification and its fire suppression capacity.

Each standardized fire extinguisher is marked with a number, indicating the amount of fuel load it can suppress, and a letter, identifying the fire class it is designed for (e.g., 34A 233B). This rating is often more important than the weight or volume of the extinguishing agent because some extinguishers with a smaller amount of agent may have a higher fire rating than larger ones. In other words, an extinguisher can be smaller, lighter, and contain less agent, yet still be capable of suppressing a larger fire.

MASS OR VOLUME OF FIRE EXTINGUISHING AGENT

Also known as the charge, this refers to the amount of extinguishing agent contained in the fire extinguisher. It is expressed in litres or gallons for liquids, and in kilograms or pounds for solids (e.g., dry powder) or gases stored in liquid phase under pressure inside the vessel (e.g., CO2 and clean agents).

The quantity of the extinguishing agent should be considered when selecting fire extinguishers, especially in cases where the fire rating is similar or ambiguous due to specific testing requirements under applicable standards.

For example, two European fire extinguishers for Class F fires from the same manufacturer, one with 6 litres and another with 9 litres of extinguishing agent, may both carry the same rating (e.g., 75F), even though the 9-litre extinguisher contains 3 litres more suppressant than the 6-litre one.

In some cases, to ensure a higher level of protection, it may be more appropriate to choose extinguishers with a larger quantity of extinguishing agent regardless of the certified fire ratings.

REGULATORY FRAMEWORK AND APPLICATION

Even if two fire extinguishers contain the same extinguishing agent and amount, they may differ significantly in their approvals and design based on the environment where they will be used.

A fire extinguisher suitable for industrial use may not be appropriate for a marine application, more corrosive environment, a hyperbaric chamber operating at pressures above 1.4 atm, or a room housing an MRI scanner where ferrous materials could cause interference. In most cases, selecting the correct fire extinguisher requires considering the specific scenario and complying with applicable regulations and certifications.

For assistance in choosing and maintaining the right fire extinguishers for your needs, please contact our sales and service teams.